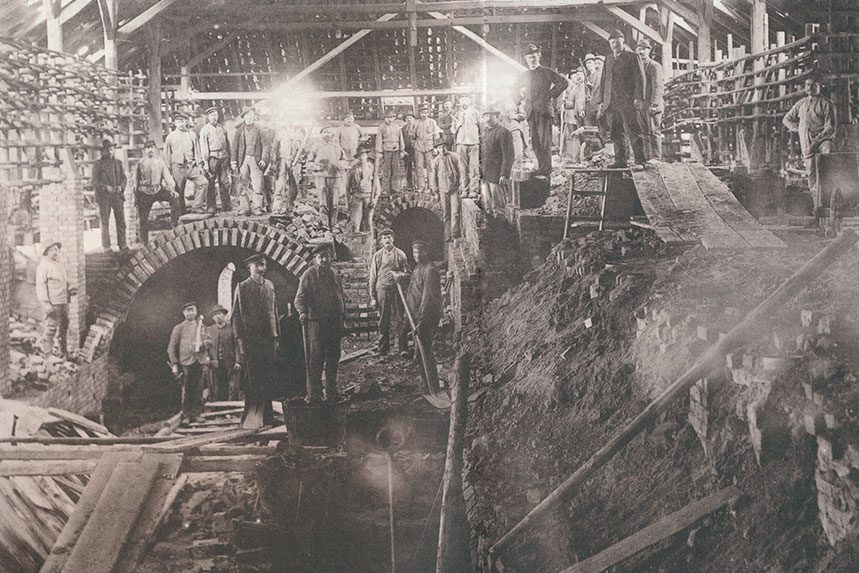

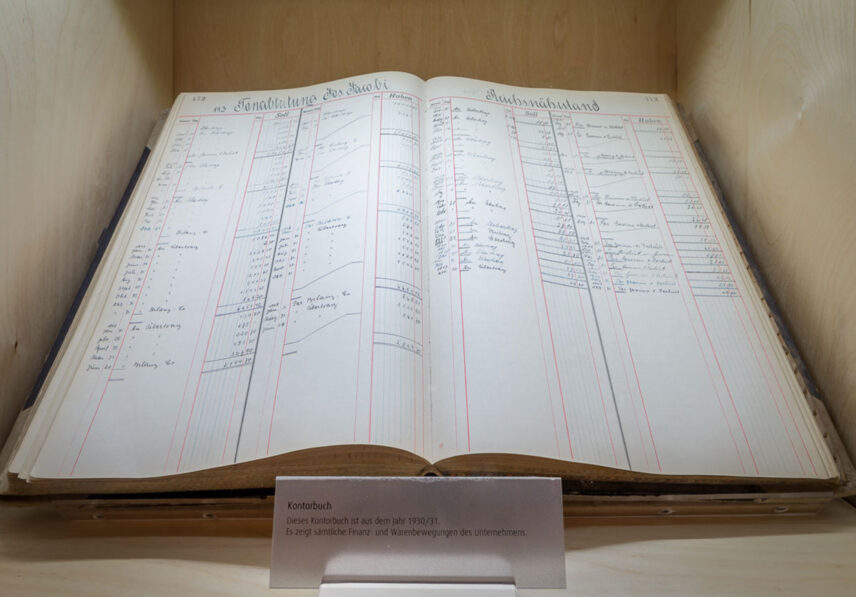

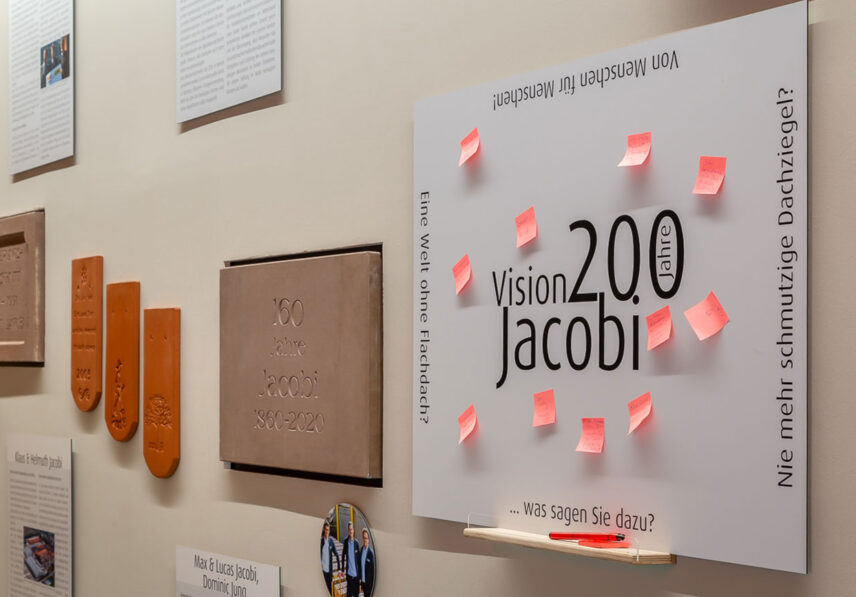

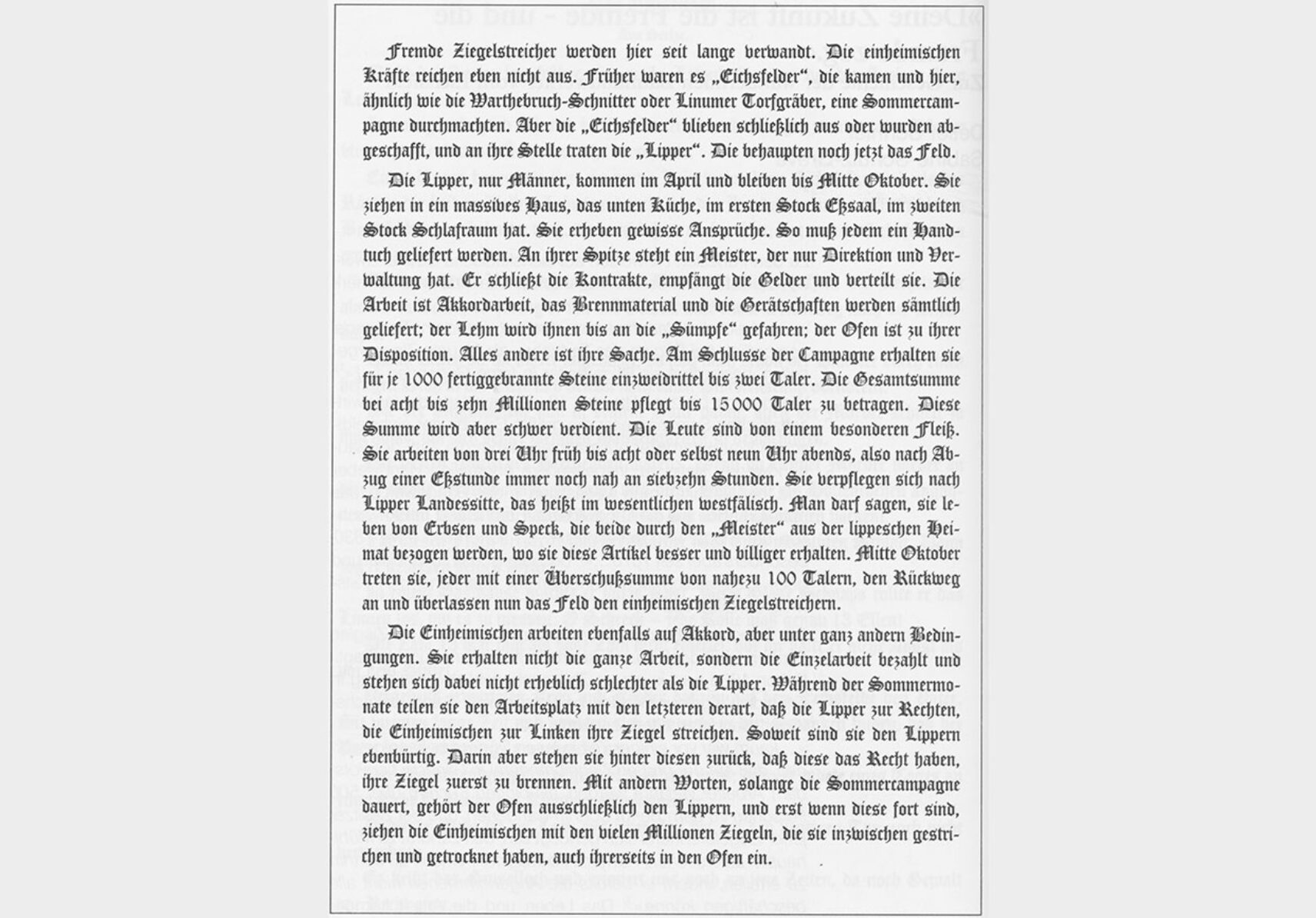

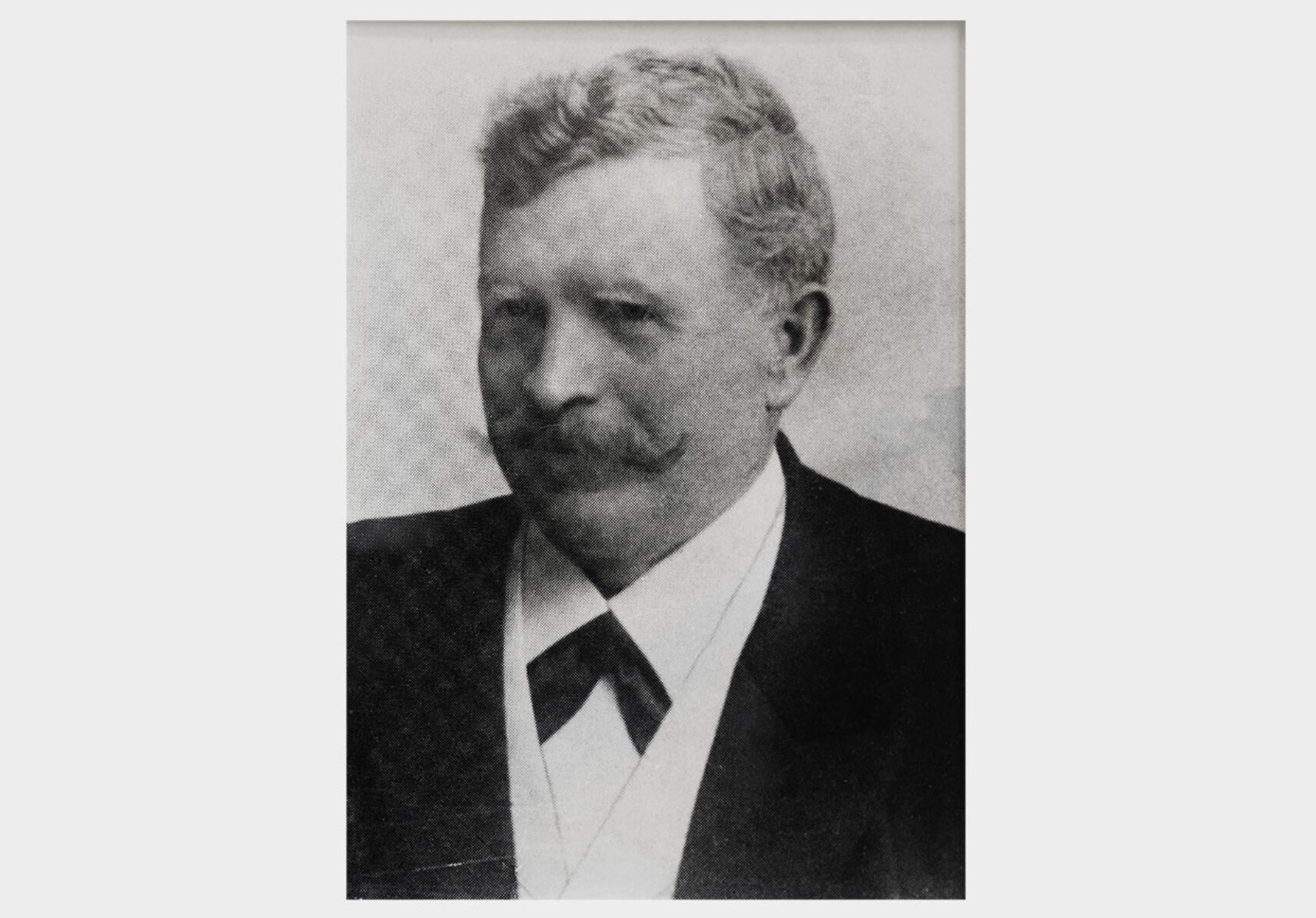

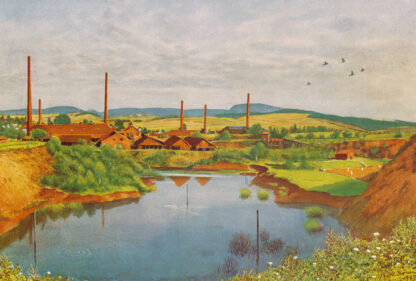

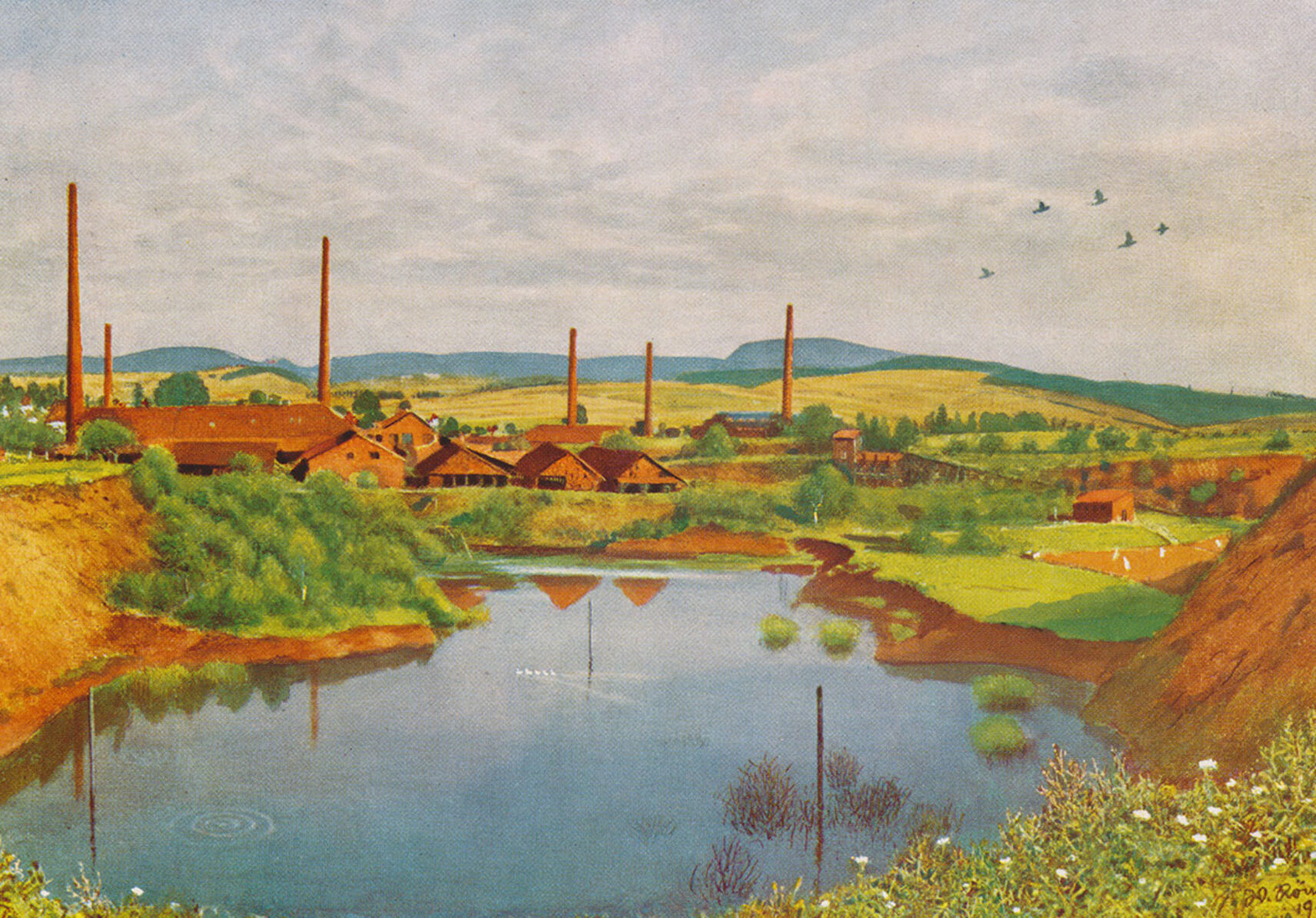

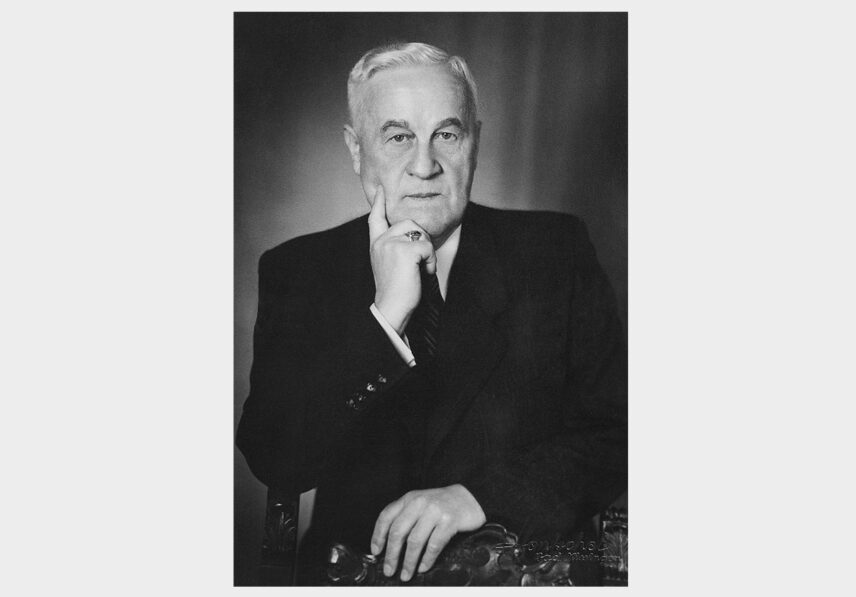

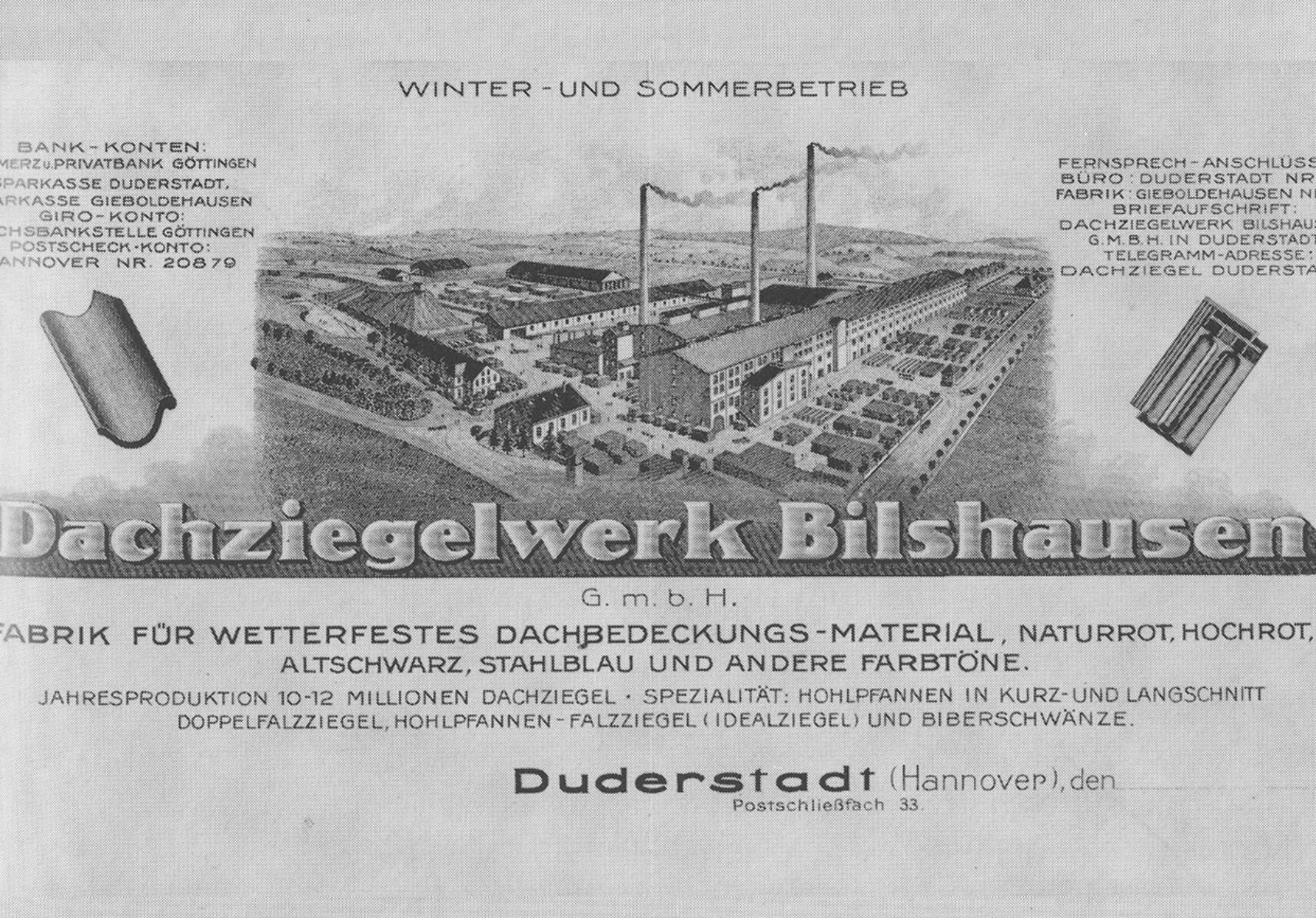

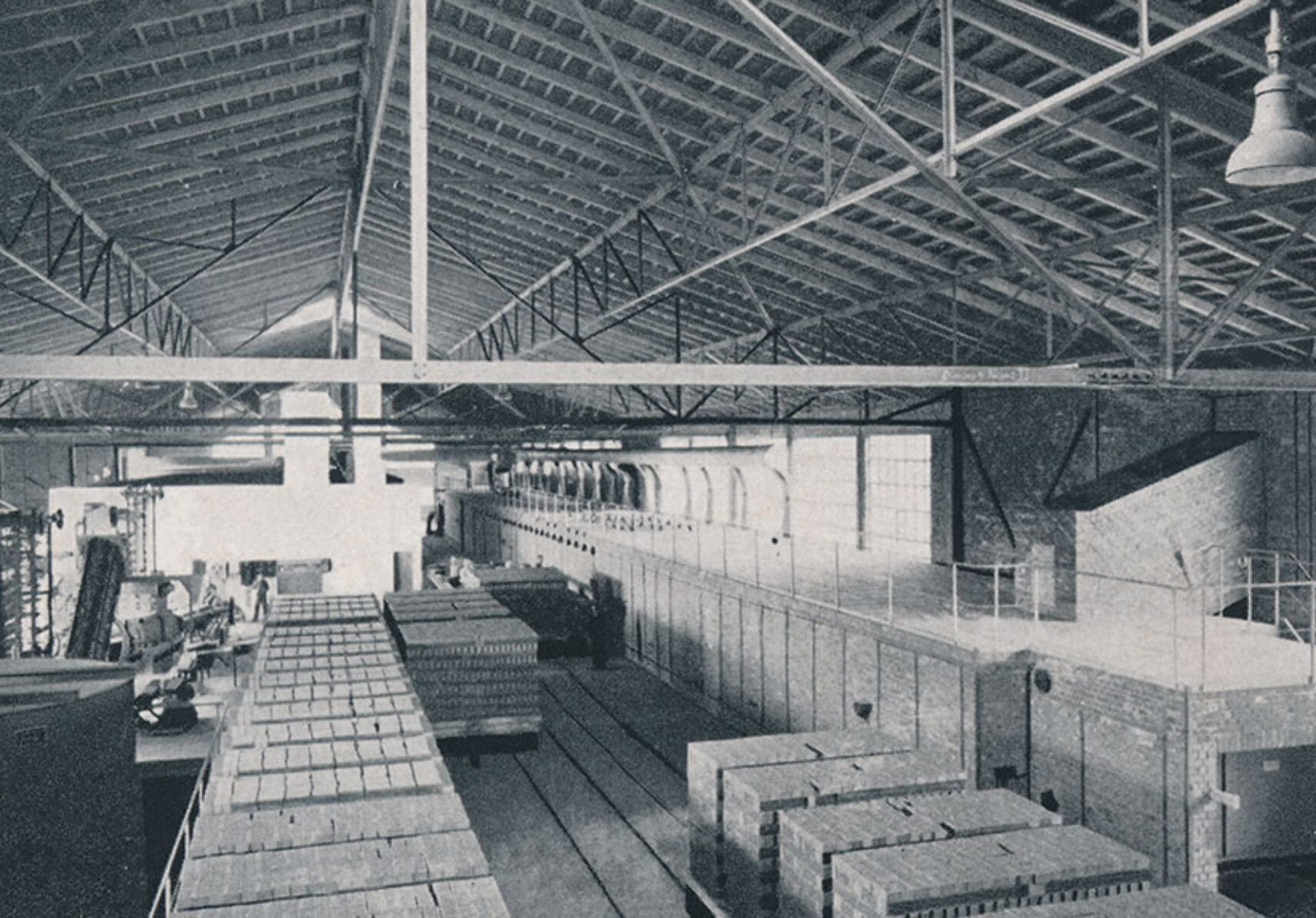

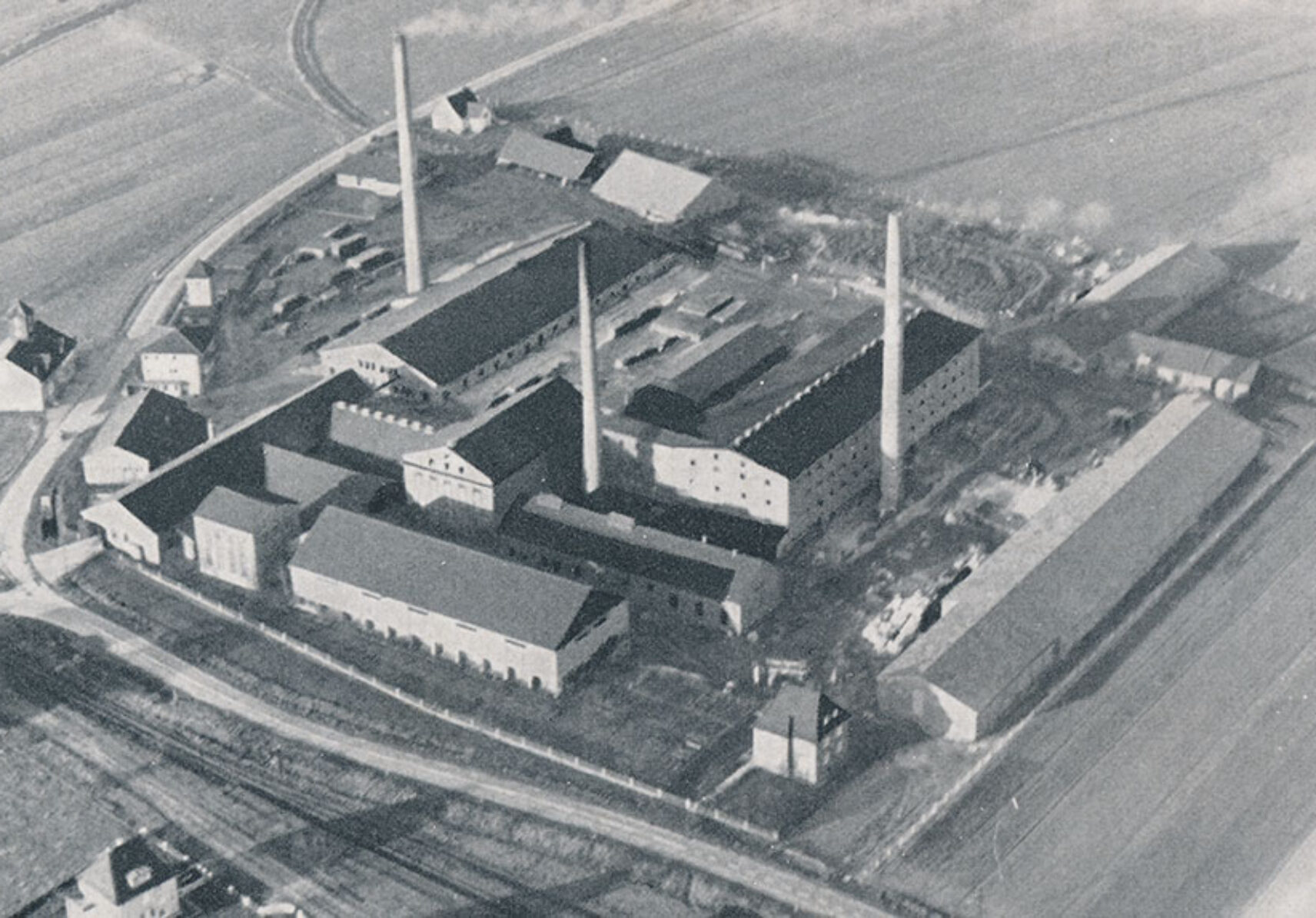

Jacobi Dachziegel has been around for more than 165 years. We are a medium-sized family business, now in its sixth generation, and are experts in our clay roof tiles. As a medium-sized family business, we produce our clay roof tiles today with a qualified team of 400 employees at two locations in Germany. Each past generation has influenced the company image, the corporate philosophy, the products and the German tile market in its own unique way. We can look back on an eventful history that has shaped us and our values and goals to this day.

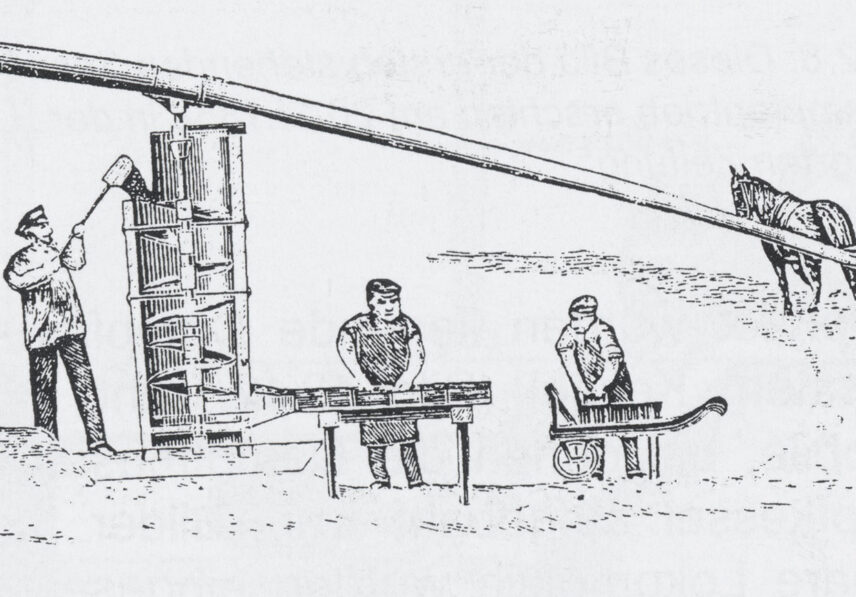

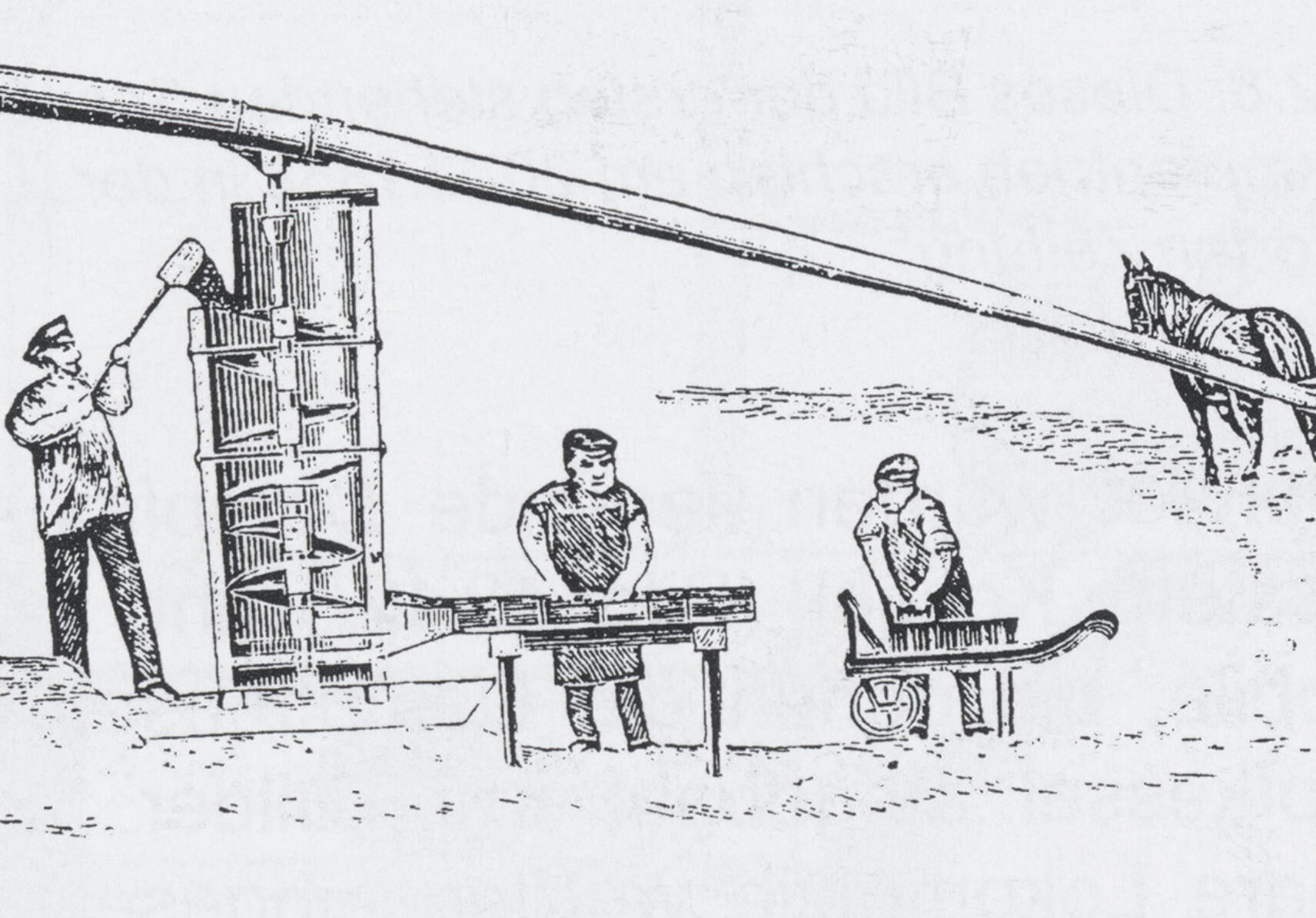

We are so proud of our origins that we have set up a museum at our Bilshausen site. Our small museum highlights all 6 generations of brick production in a personal way and brings the viewer closer to where we come from.