A sustainable value chain is particularly important to us. Every Jacobi tile is a purely natural product, for your durable, long-lasting and aesthetic roof. Clay is an original building material and has been used for construction since early history.

Sustainability & quality

Roof tiles are a natural product

From nature into nature

Careful dismantling

Our clay is extracted regionally. We operate our own clay pits at both production sites in Bilshausen & Langenzenn. Our raw material is our most valuable asset. We work with it in an environmentally friendly and resource-efficient manner. To this end, we recultivate our clay pits and ensure short access routes. Our roof tiles are 100% made in Germany.

Precise production

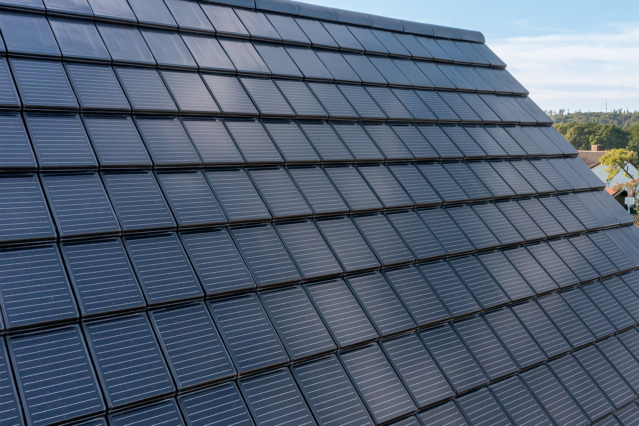

To make our production even more environmentally friendly, we produce our own electricity with our solar systems at both the Bilshausen and Langenzenn sites. We are constantly optimizing processes and machines to improve efficiency and extend the service life of our products and the production machines we use.

Long-term use

Choosing a roof from Jacobi is usually a decision for life. Our roof tiles are weather-resistant, color-fast and will protect your home for many decades. The fifth façade radiates comfort and, depending on the choice of color and model, plays a key role in determining the appearance of your property.

Recyclable disposal

Our high-quality clay roof tiles are 100% recyclable. After decades of use on the roof, the fired clay can be recycled, e.g. as “tile sand” on hard courts and tennis courts or as a planting substrate for cities and green roofs. A genuine natural product!Monitoring of all production stages

Quality assurance

We process natural raw materials whose composition always varies slightly. In order to react quickly to precisely these fluctuations, we monitor each individual production stage very closely. Our quality assurance is not only extremely important for a consistent product with a long service life, but also helps us to save energy. Deviations in the raw material or on machines are detected at an early stage, enabling rapid correction and preventing unnecessary use of energy or materials.

Quality control of the surface color

Quality control of strength, the so-called breaking test

Optimal use of energy

Energy management

A major corporate objective is to use energy responsibly and to constantly examine and optimize production processes to this end. Plant management, material testers and stove masters work hand in hand here – the top priority is the quality of our roof tiles and their accessories. Our energy management has been certified in accordance with ISO 50001, a European standard that is recognized worldwide, since 2012. The main objective of the annual certification is, quite simply put, to save energy in order to avoid harmful greenhouse gases and fossil greenhouse gas emissions.

Sustainability and environmental awareness at Jacobi

The annual ISO 50001 certification and the many individual measures, process improvements and the resulting increase in efficiency in the use of energy have already achieved a great deal over the past 12 years. All values and figures are documented in detail in the annual energy report, prepared by an independent certifier and monitored by the responsible federal authority.

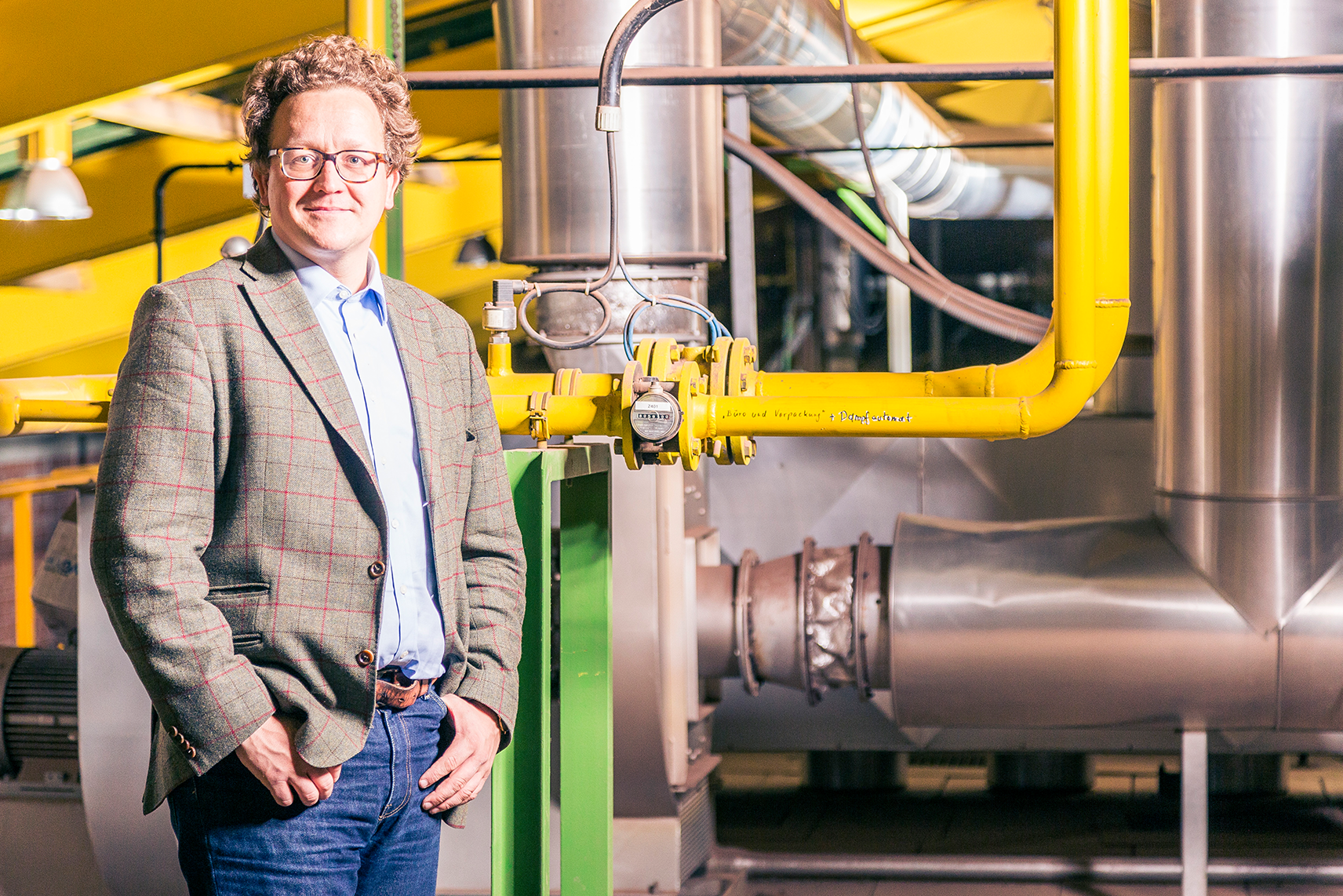

That alone is not enough for us. The first step towards generating our own electricity was taken in 2016 with our own gas-fired combined heat and power plant (CHP), which we use to generate electricity efficiently. We use the waste heat to heat the office buildings in Bilshausen, among other things. This major step is the result of regular discussions with the district of Göttingen and regional decision-makers. New energy policy options, e.g. for generating electricity, are repeatedly analyzed and discussed from all angles for the benefit of the region.

Building blocks in daily activities

A matter of course for us

Small things – big impact. Environmentally conscious action starts with the small everyday things, has already changed our processes significantly in recent decades and will continue to do so in the future.

Environmentally conscious recycling & disposal

The unbreakable transportation of our bricks and their accessories is important and essential. Residual materials and waste are recycled wherever possible. For example, transport packaging (films, bundling tapes) is taken back, recycled or disposed of properly.

Saving resources and using them sustainably

At Jacobi Tonwerke, we use gas as a fossil fuel in a very considered and environmentally conscious manner. Firing processes are strictly monitored, production times and processes are carefully considered and planned for the long term; always with the aim of keeping absolute energy consumption as low as possible. The waste heat from our kilns is also used for the drying process of our bricks, for heating and for hot water preparation.

Space for plants and animals

An enormous diversity of species, both plants and animals, has developed in our clay pits over the decades. No agricultural use, pesticides or fertilizers are certainly the main reason for this positive development. But our recultivation, which we carry out responsibly in close cooperation with the nature conservation authority, also contributes significantly to this. We plant trees & shrubs and create small ponds. Simply a paradise for plants and animals!

Future-oriented production & further development of products

We work closely with research partners to make production processes and techniques more CO2-neutral and to improve the properties of our products.Our commitment

Because it is close to our hearts

We are committed to a greenhouse gas-neutral brick industry and are actively helping to shape it. For example, our Managing Director Dominic Jung was involved in designing the “Roadmap for a greenhouse gas-neutral brick industry in Germany” by FutureCamp on behalf of the Federal Association of the German Brick and Tile Industry.