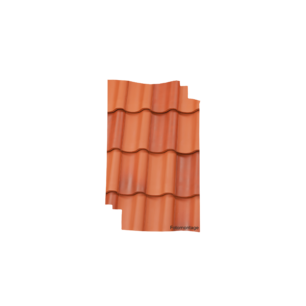

Our roof tiles are a natural product consisting of three basic elements: clay, water and fire. Find out more about the production of our quality roof tiles and our raw material from regional pits.

Variety and individuality with ceramic roof tiles from Jacobi

Quality clay

Three steps to the finished product

Did you know?

About clay

Jacobi operates two pits of its own under very different conditions. Our pit near Bilshausen in Lower Saxony is in what is known as the red sandstone region. The quality clay there was formed some 250 million years ago when the landscape of the region was dominated by lakes. Generally, bodies of water have a positive effect on clay deposits, which was a stroke of luck for this traditional family company. Decades ago, the Jacobi family was already researching the perfect mixing ratios for roof tiles and bought in raw material from other clay pits. And they were very successful! Our Jacobi products are all about robustness, longevity and a particularly fine finish.

Our clay from Langenzenn

There is lots of ‘Lahma’ or lime in the tile works in the town of Langenzenn. Roof tile production has been a tradition in Langenzenn for a long time because of it. In geological terms, our quality clay from the Franconian scarpland belongs to the South German Scarpland, while in terms of the history of the Earth, it is part of the Keuper formation. The raw material formed and was deposited in Langenzenn some 230 million years ago, and the fact it is deposited in layers makes it an excellent raw material for quality clay tiles. The layers can clearly be seen on the aerial view. An exact analysis of each individual layer carried out in our own laboratory shows elements of sand, clay and marl which we selectively extract and use to create the optimum mix.

Basis of life

Element of water

Water is a key element of our production process. The raw material needs to contain around 20 % water in order to achieve the ideal malleability and bendiness. Soil moisture levels are around 10 – 15 %, depending on precipitation and the time of year. This means we have to top up the remaining liquid. At the production site in Langenzenn, we use surface water straight from the pit and in Bilshausen we extract the water from our own spring. This is why we prepare the resource and feed it back into the production cycle. Careful and conscious handling of this precious commodity is part of our ethos.

Insight into our production

How our tiles are produced …

Clay and sand are extracted from pits, mixed and gradually broken down to the grain required by passing through the crusher, panmill and rolling mills in turn, with water added all the time. In the clay store, known as the ‘soaking house’ in Langenzenn, the tile clay is stored for an interim period before the crushed and homogenised clay material is fed into the press.

Production insights

A vacuum extrusion press

is used to produce a clay column from which either extruded roof tiles (e.g. plain tiles) can be produced directly, depending on the tile form required, or clay chunks are formed which are the precursor for pressed roof tiles. The next step is to feed these clay chunks into a press fitted with plaster moulds and press them under high pressure to form pressed roof tiles (e.g. flat roof tiles).

Production insights

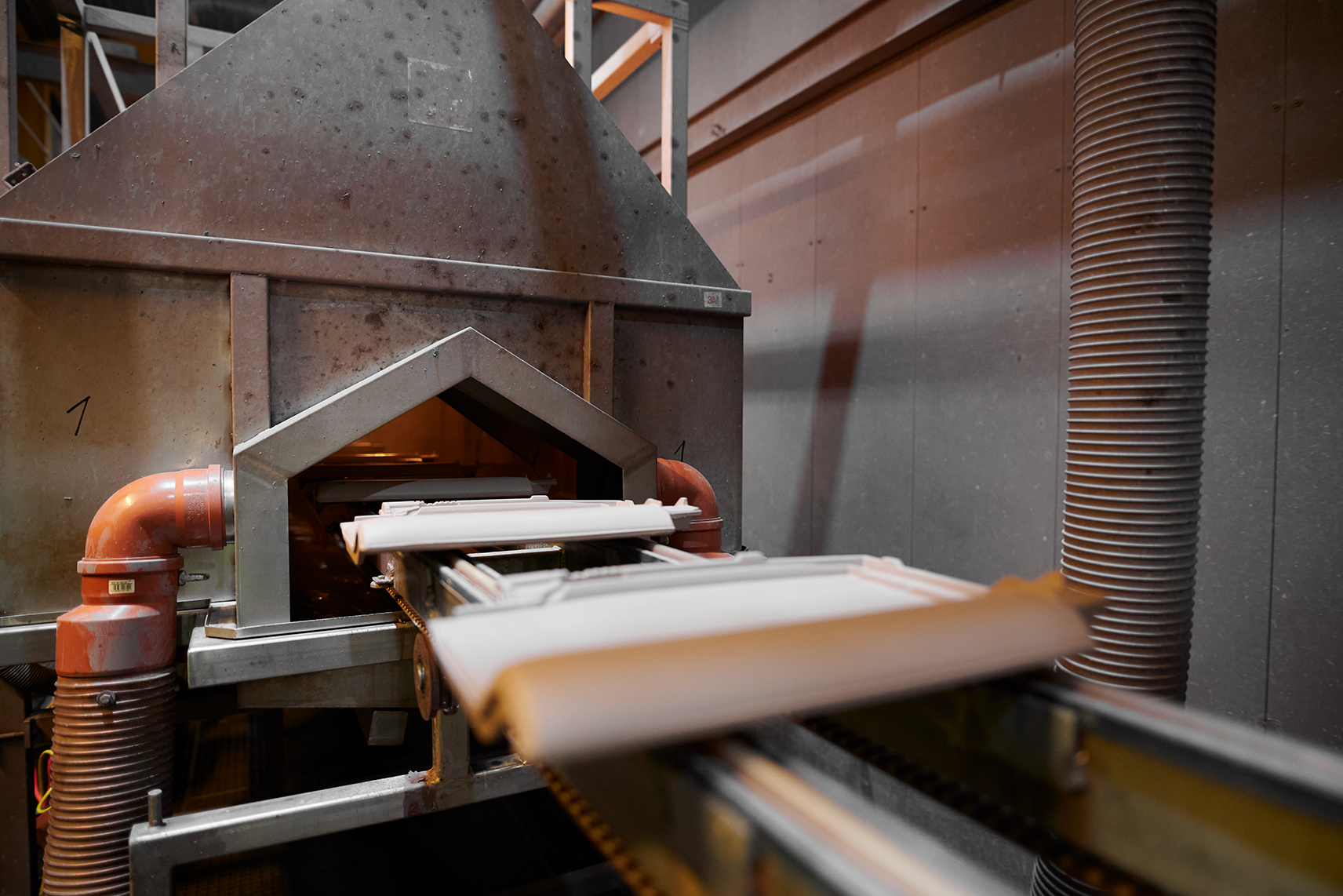

After pressing,

the final tile design is already evident. The pressed tiles are fed into the drying process on drying frames. The natural red tiles are then taken directly to the furnace and afterwards they are prepared for transport. All other tiles are given the required colour finish and then fired.

And the result is …

the Jacobi product range

Our local clay is used to make 20 different roof tiles in more than 50 different colours at our production sites in Bilshausen and Langenzenn. The mixing ratios for the raw material depend on the finish required, be it natural red, engobed, luxury engobed or glazed from the Avantgarde Collection.

Quality finishes mean an almost endless selection and you are bound to find the perfect ceramic roof tiles for any property. Find inspiration in the range of Jacobi ceramic roof tiles. Have you already found our references with the handy filter options?

Our style consultants will be happy to help

Got your own ideas?

No matter how far along you are with your decision on the perfect roof tiles, a personal consultation with our experts is bound to help. We have roof tiles for all types and solutions to all technical problems.

You can find your own contact person, style consultant, or ‘solution finder’.